热搜关键词: TPU TU厂家 TPE D系列线材料 TPE插头料

线材插头料阻燃CZR系列

本产品是一款以SEBS为基材的高性能高分子材料,可注塑成型,有着良好的成型性 This product is a high performance polymer material with SEBS as the substrate, it can be injection molding, has a good formability

服务热线:138-2921-7046

|

产品说明Product description |

|

|||||||||

|

本产品是一款以SEBS为基材的高性能高分子材料,可注塑成型,有着良好的成型性

This product is a high performance polymer material with SEBS as the substrate, it can be injection molding, has a good formability |

|

|||||||||

|

关键特性Key characteristic |

|

|||||||||

|

1,表面半雾面,手感细腻 Surface semi matte surface, feel fine

2,耐候性能佳,不易黄变 Weather performance is good, not easy to yellow

3,易成型,不缩水 Easy molding, not shrink |

|

|||||||||

|

功能Function |

|

|||||||||

|

产品应用

Main application |

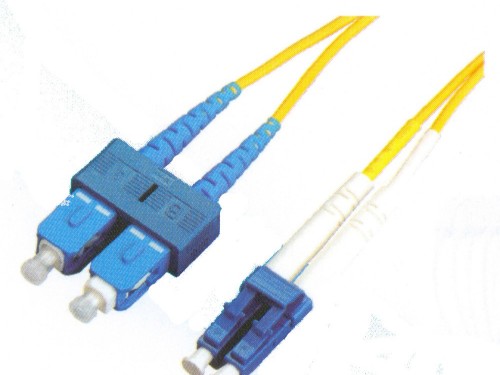

电线电缆Wire and cable |

电线插头Wire plug |

|

|||||||

|

|

|

|

||||||||

|

加工方法Processing method |

注塑成型Injection molding |

|||||||||

|

环保认证

Environmental certification |

ROHS |

REACH |

EN71-3 |

|

||||||

|

|

PAHS |

ASTM-F963 |

Phthalate |

|

||||||

|

颜色Color |

本色Natural |

|

||||||||

|

气味Smell |

少许树脂味A little resin smell |

|

||||||||

|

外型Appearance |

圆球形小颗粒Cylindrical particle,about 3mm×1.5mm |

|

||||||||

|

储藏期Storage period |

常温下通风干燥,24个月Ventilated dry at normal temperature ,about 24 months |

|

||||||||

|

包装方式Packaging method |

25公斤/袋 25kg/bag |

|

||||||||

|

物理性能Physical properties |

结果Result |

单位Unit |

方法Method |

成型条件Molding condition |

|

|||||

|

比重Specific gravity |

1.16±0.02 |

g/cm3 |

ASTM D792 |

干燥温度Drying temp 80℃ |

|

|||||

|

硬度Hardness |

75±5 |

shoreD |

ASTM D2240 |

干燥时间Drying time 2Hours |

|

|||||

|

拉伸强度Tensile strength |

>3 |

Mpa |

ASTM D412 |

射嘴温度Nozzle temp 190℃ |

|

|||||

|

断裂延伸Elongation at break |

<500 |

% |

ASTM D412 |

螺筒一段温度Screw 1 temp 180℃ |

|

|||||

|

撕裂强度Tearing strength |

>20 |

Kn/m |

ASTM D624 |

螺筒二段温度Screw 2 temp 170℃ |

|

|||||

|

熔融指数Melt index |

>18 |

g/10min |

ASTM D1238 |

螺筒三段温度Screw 3 temp 160℃ |

|

|||||

风靡全球的新型环保材料,雄聚TPE材料六大特点

TPE材料具有良好的弹性和柔软性,与人体皮肤具有很好的亲和力

TPE材料的使用范围最低可达-50℃,最高可达140℃。具有良好的耐候性

TPE材料不但可以单独加工成品,还可以二次注塑、吹塑、共挤等方式与其他材料粘结

TPE材料拥有有益的耐水、耐弱酸、耐弱碱性能。可耐汽油、柴油、化妆品等日常化学品

TPE材料可按进行注塑成型挤出成型和改塑成型,生产效率高,加工方便,高效,品质稳定易控

安全无毒,产品可达标RoHSREACH、FD等环保标准。边角料,水口料可回收循环使用

从2003至今,雄聚已发展为弹性体材料行业内生产制造商,从台湾到大陆,进而行销全球业务范围,覆盖三十多个国家和地区。雄聚现有16000余平方的生产工厂,各类成熟挤出生产线12条,年产能达18000吨,产品线涵盖30多个应用领域,是行业内规模较大厂商之一。